Zinc Oxide Growth on Nickel Foam

This website provides a comprehensive guide to the growth of zinc oxide (ZnO) nanostructures on nickel foam substrates. The combination of ZnO's unique properties with nickel foam's three-dimensional porous structure creates materials with enhanced performance for various applications including energy storage, catalysis, sensing, and more.

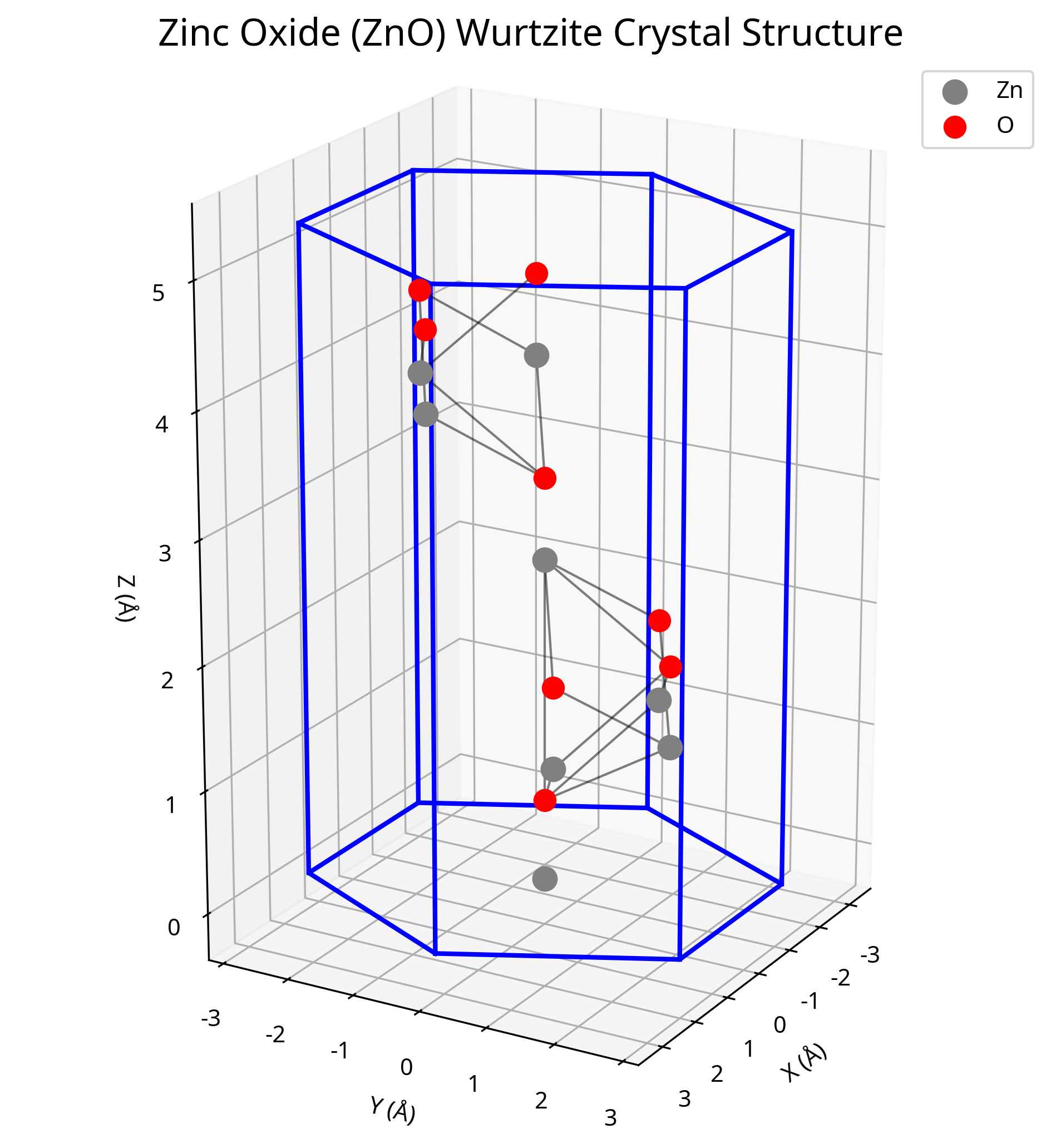

Figure 1: Crystal structure of zinc oxide showing the hexagonal wurtzite arrangement.

Zinc Oxide Properties

Zinc oxide is a versatile semiconductor material with unique physical and chemical properties that make it suitable for a wide range of applications.

Nickel Foam as a Substrate

Nickel foam provides an excellent three-dimensional substrate for growing zinc oxide nanostructures due to its high surface area, good electrical conductivity, and mechanical stability.

Growth Methods

Several methods can be employed to grow zinc oxide nanostructures on nickel foam. The three main approaches are hydrothermal synthesis, chemical vapor deposition (CVD), and electrodeposition.

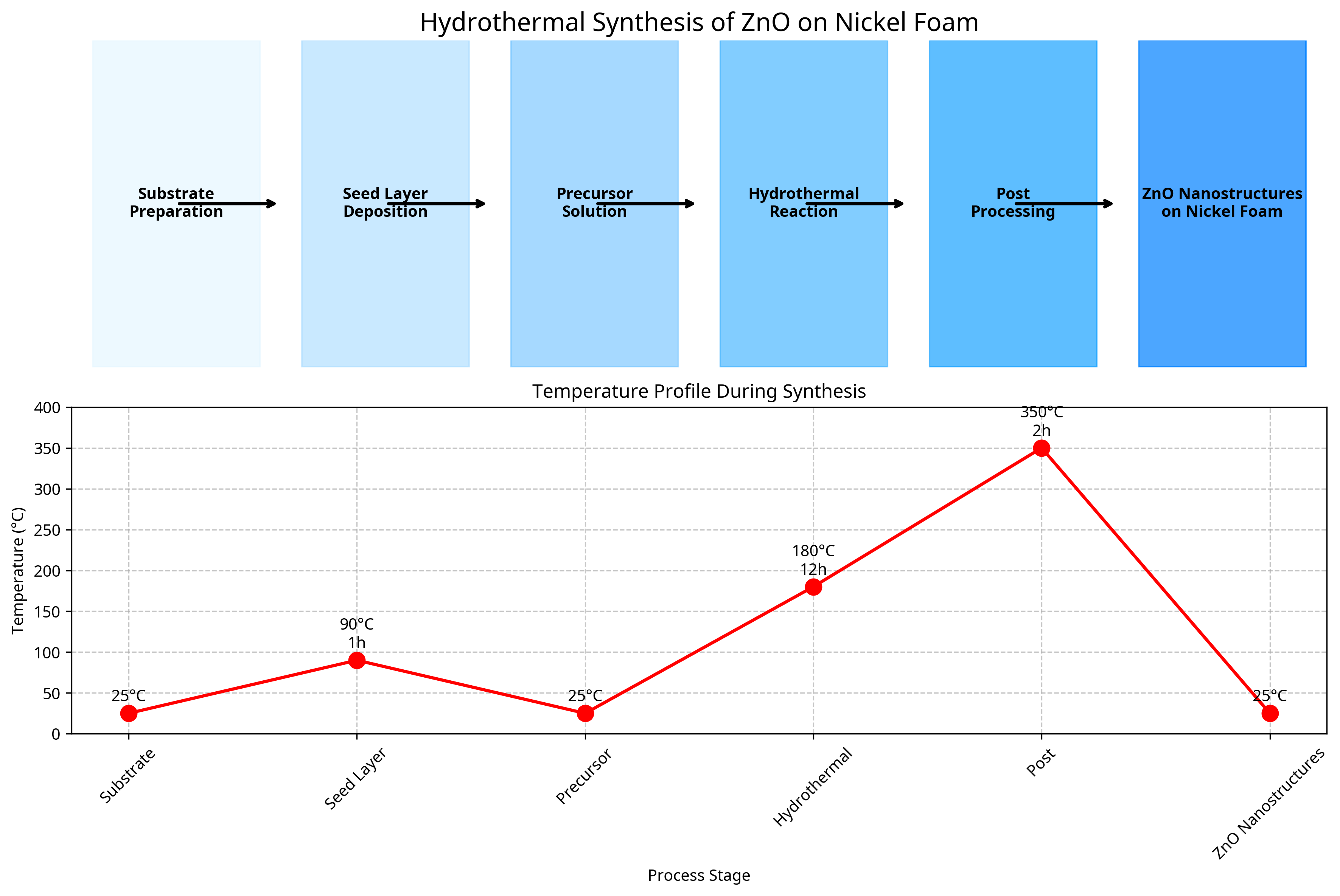

Hydrothermal Synthesis

Hydrothermal synthesis is a solution-based method that involves the growth of ZnO crystals from aqueous solutions at elevated temperatures and pressures in a sealed vessel.

Figure 2: Schematic representation of the hydrothermal synthesis process for growing ZnO on nickel foam.

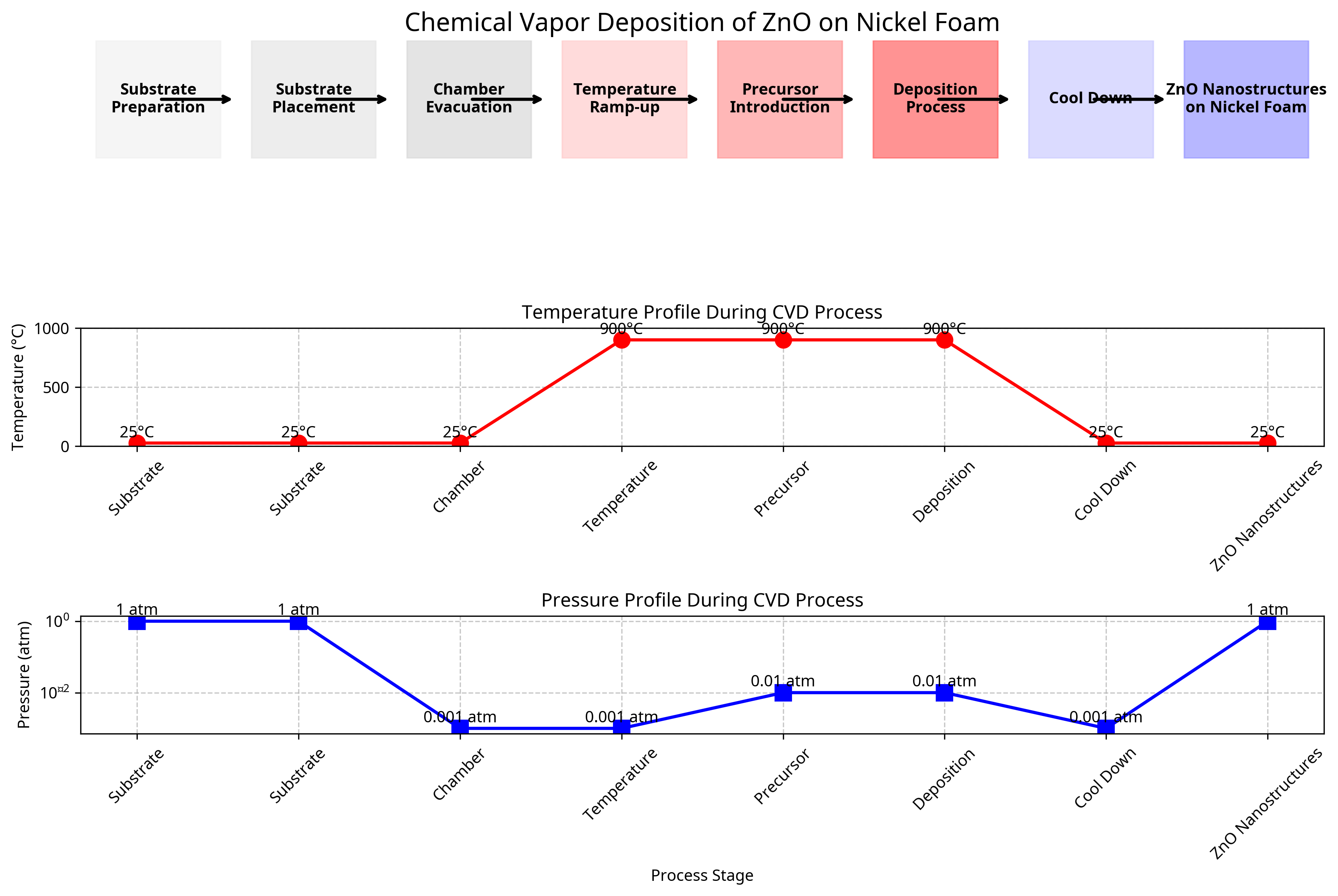

Chemical Vapor Deposition (CVD)

Chemical vapor deposition is a process where zinc-containing precursors in the vapor phase react to form ZnO on the nickel foam substrate.

Figure 3: Schematic representation of the chemical vapor deposition process for growing ZnO on nickel foam.

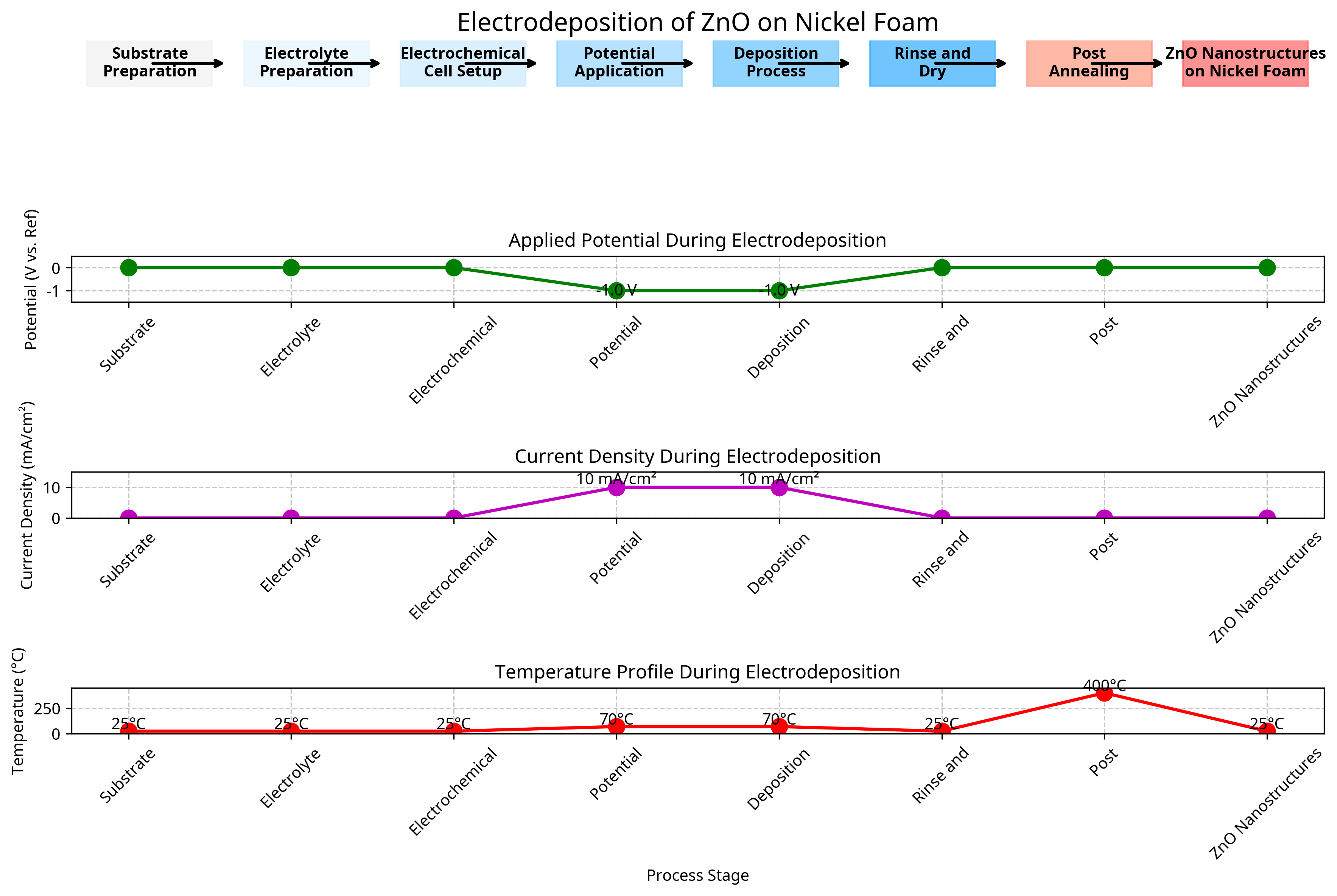

Electrodeposition

Electrodeposition is an electrochemical process that uses electric current to reduce dissolved zinc ions to form ZnO coating on the nickel foam electrode.

Figure 4: Schematic representation of the electrodeposition process for growing ZnO on nickel foam.

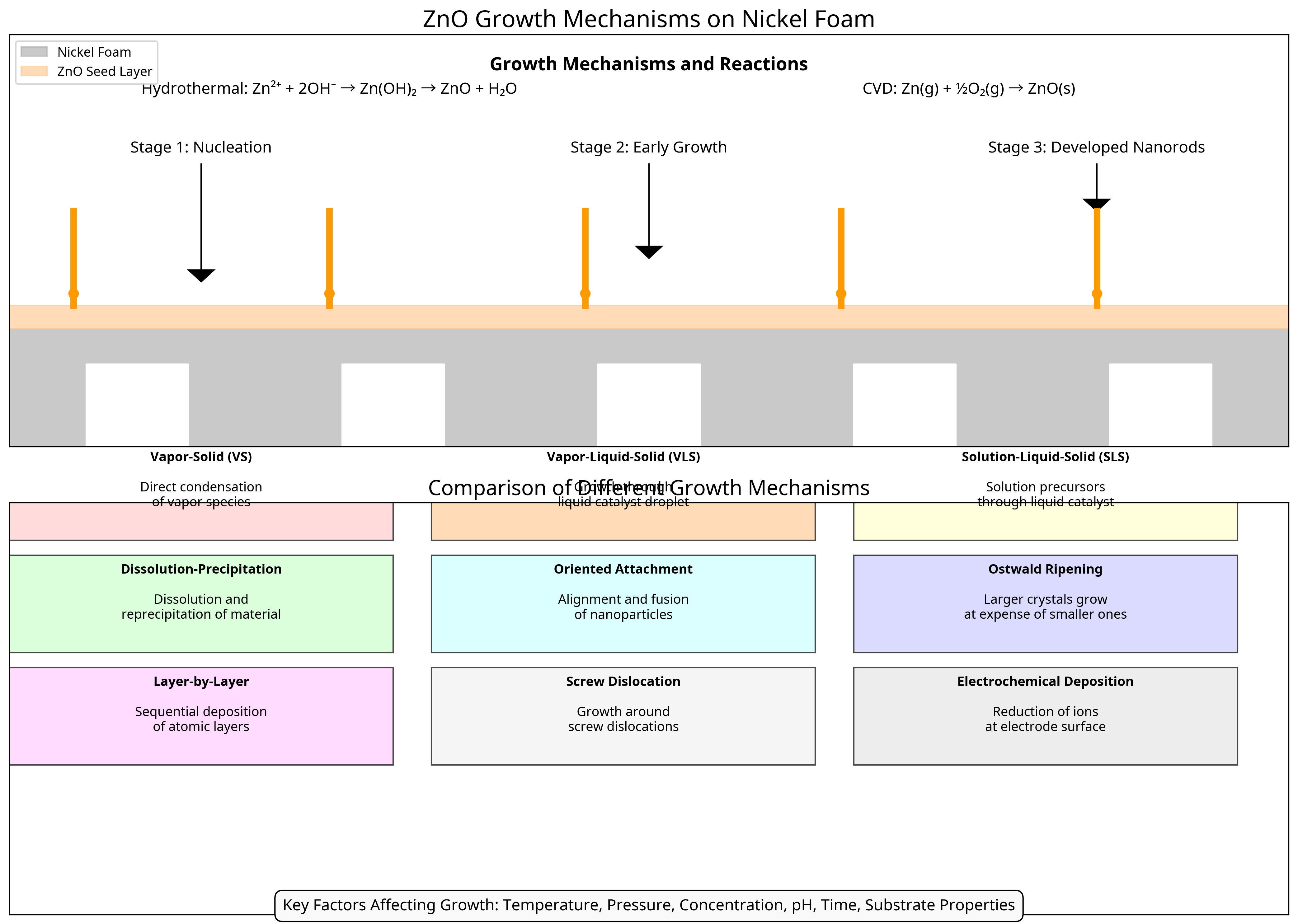

Growth Mechanisms and Kinetics

Understanding the growth mechanisms and kinetics of ZnO nanostructures is crucial for controlling their morphology, size, and properties.

Figure 5: Illustration of different growth mechanisms for ZnO nanostructures on nickel foam.

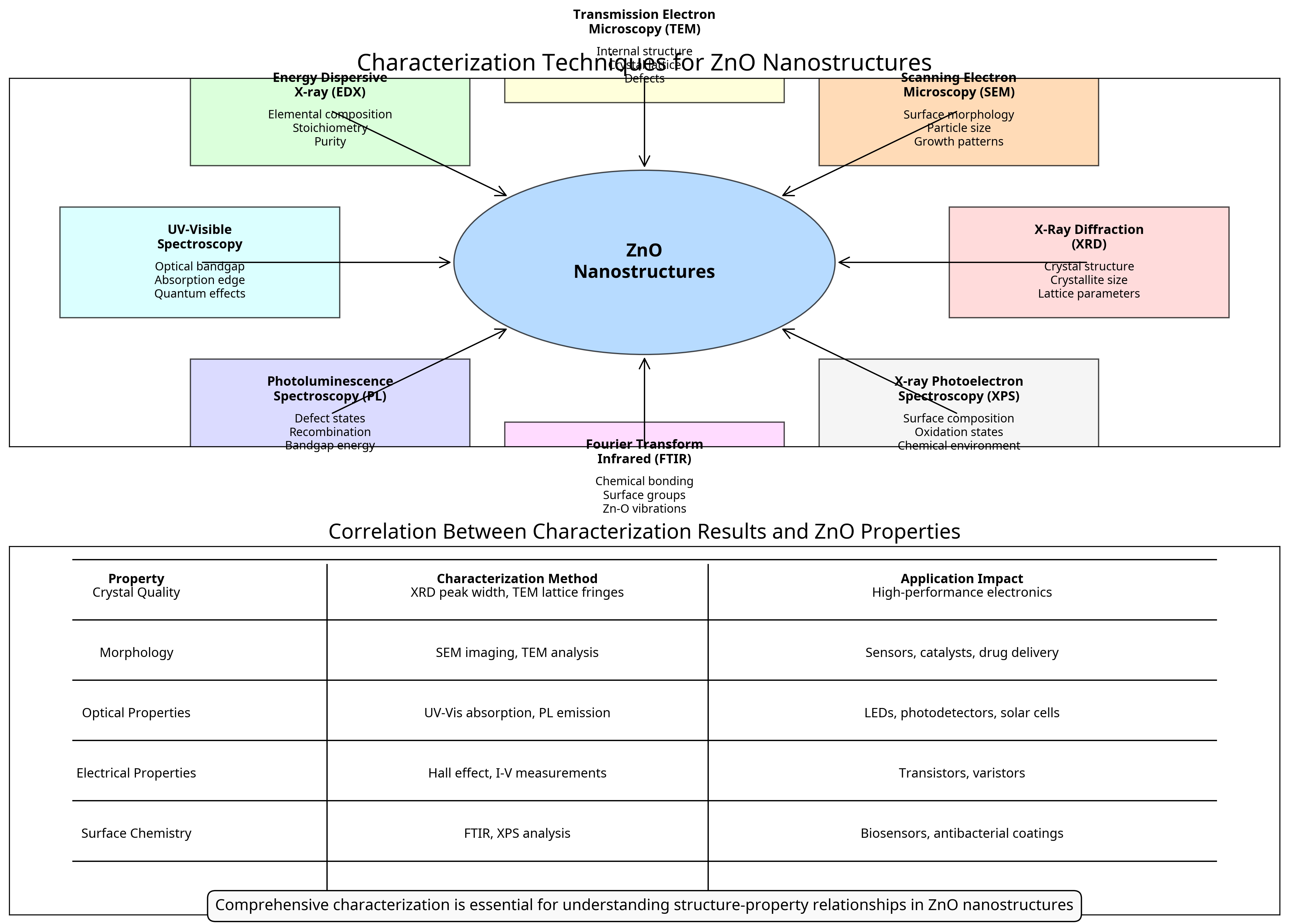

Characterization Techniques

Various characterization techniques are employed to analyze the physical, chemical, and structural properties of ZnO nanostructures grown on nickel foam.

Figure 6: Overview of characterization techniques used for analyzing ZnO nanostructures.

Applications

ZnO nanostructures grown on nickel foam find applications in various fields including energy storage, catalysis, sensing, and more.

Conclusion

The growth of zinc oxide nanostructures on nickel foam offers a promising approach for developing advanced materials with enhanced properties for various applications.